Successful chw tes design strategies basis of design chilled water is normally stored at 39 f to 42 f in the storage tanks since this temperature range is directly compatible with conventional chillers.

Chilled water thermal storage tank design calculations.

A difference of 20 f is the pract i cal maximum for most building cooling applications although a few systems exceed 30 f.

Chilled water is generally stored at 39 f to 42 f temperatures directly compati.

10 to 12 f chilled water systems ge n erally need a differential of at least 16 f to keep the storage tank size reason able.

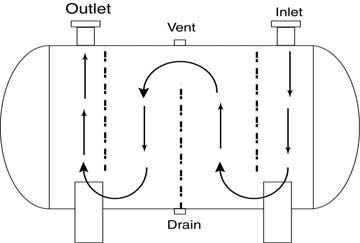

Warm and chilled water enters and exits the tank through diffusers located at the top and bottom of the tank.

Volume gallons 5 875d 2h.

Thermal energy chilled water or hot water is produced during periods of off peak electrical demand or usage collected in a thermal energy storage tank then withdrawn and distributed to the facility during on peak periods.

The return temperature is between 58 f to 60 f.

Both on peak and off peak electrical demands are expected to be reduced.

Design diffuser tank building advantages.

Chilled water tes concept tank.

By optimizing the operation of the building air handling units chilled water pumps chiller plant and the thermal storage system the storage tank is better charged while chiller run time is reduced.

The average temperature is 48 2 f so we need to calculate the water properties at this temperature.

The flow rate of chilled water into the evaporator is measured as 12 649ft3 h and the chilled water inlet temperature is 53 6 f the outlet temperature is 42 8 f.

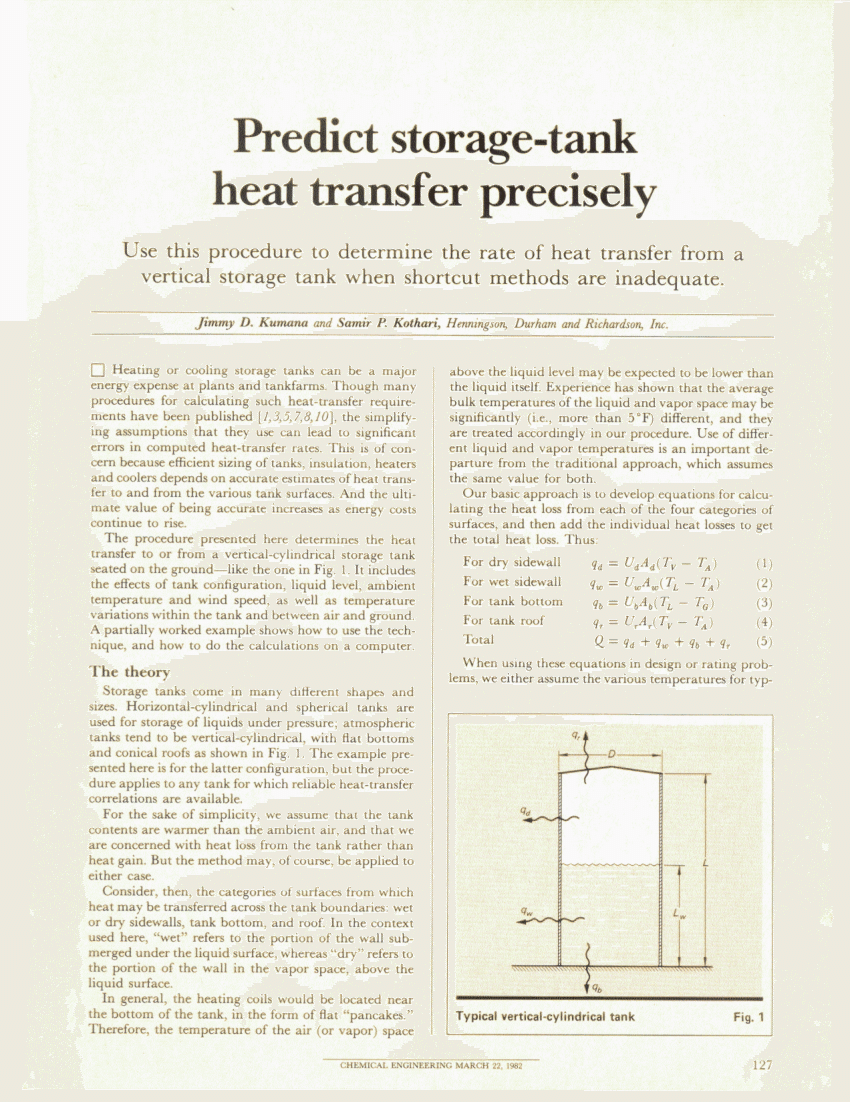

Design of chilled water storage systems stratified storage tanks estimating tank geometry tall slender tanks are preferred to optimize thermocline and minimize footprint where practical tank height should be greater than highest air vent in chilled water lines prevents drainback quick formula for tank sizing.