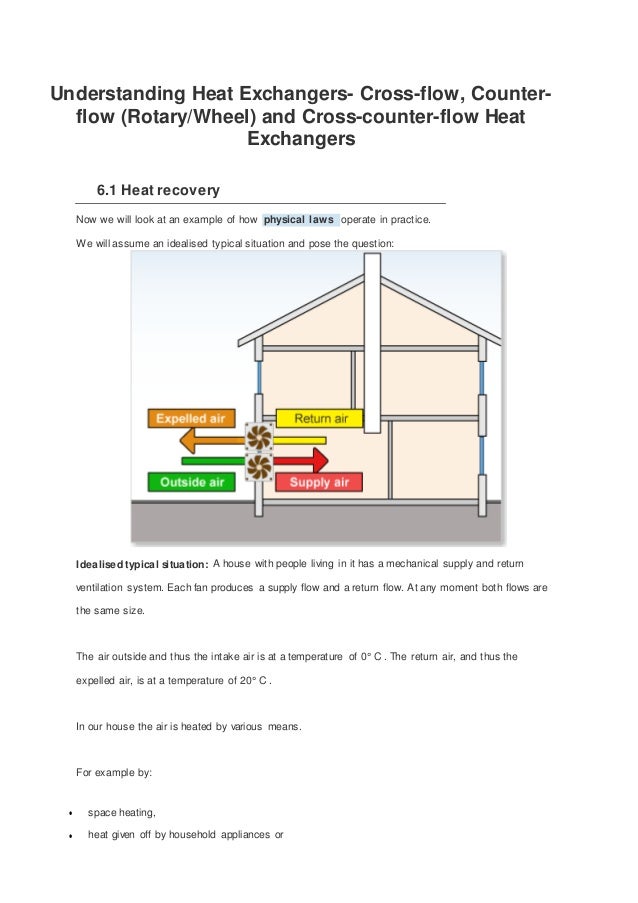

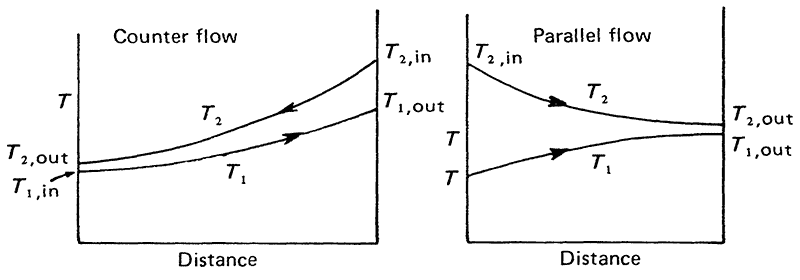

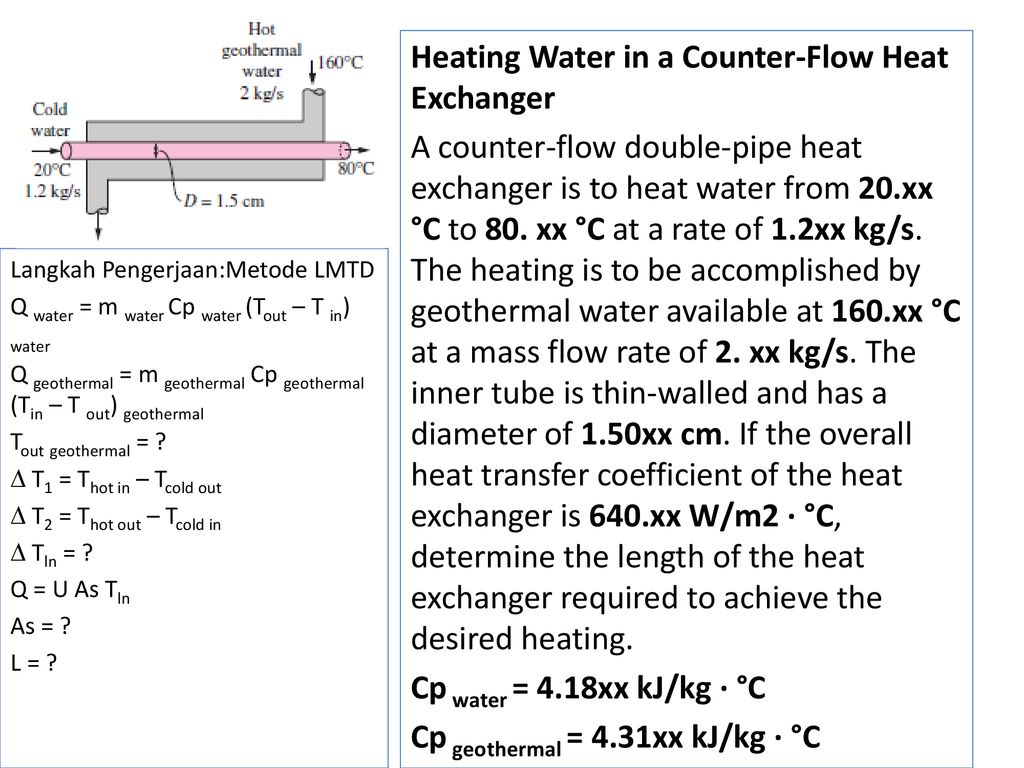

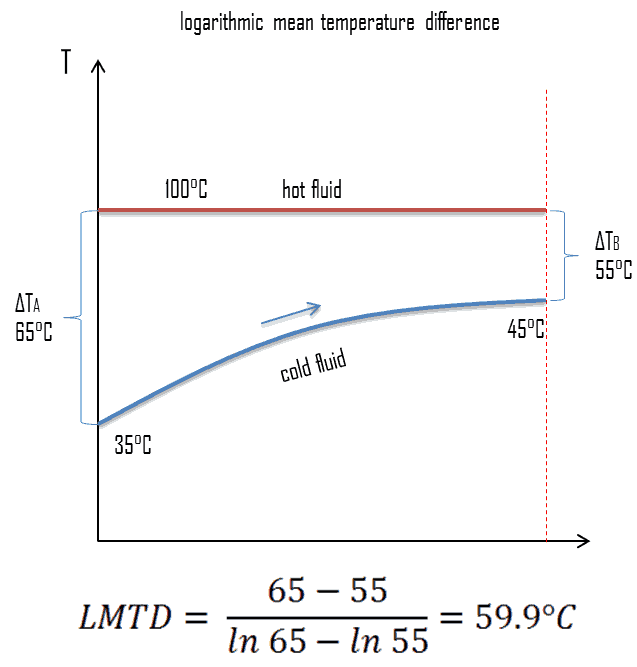

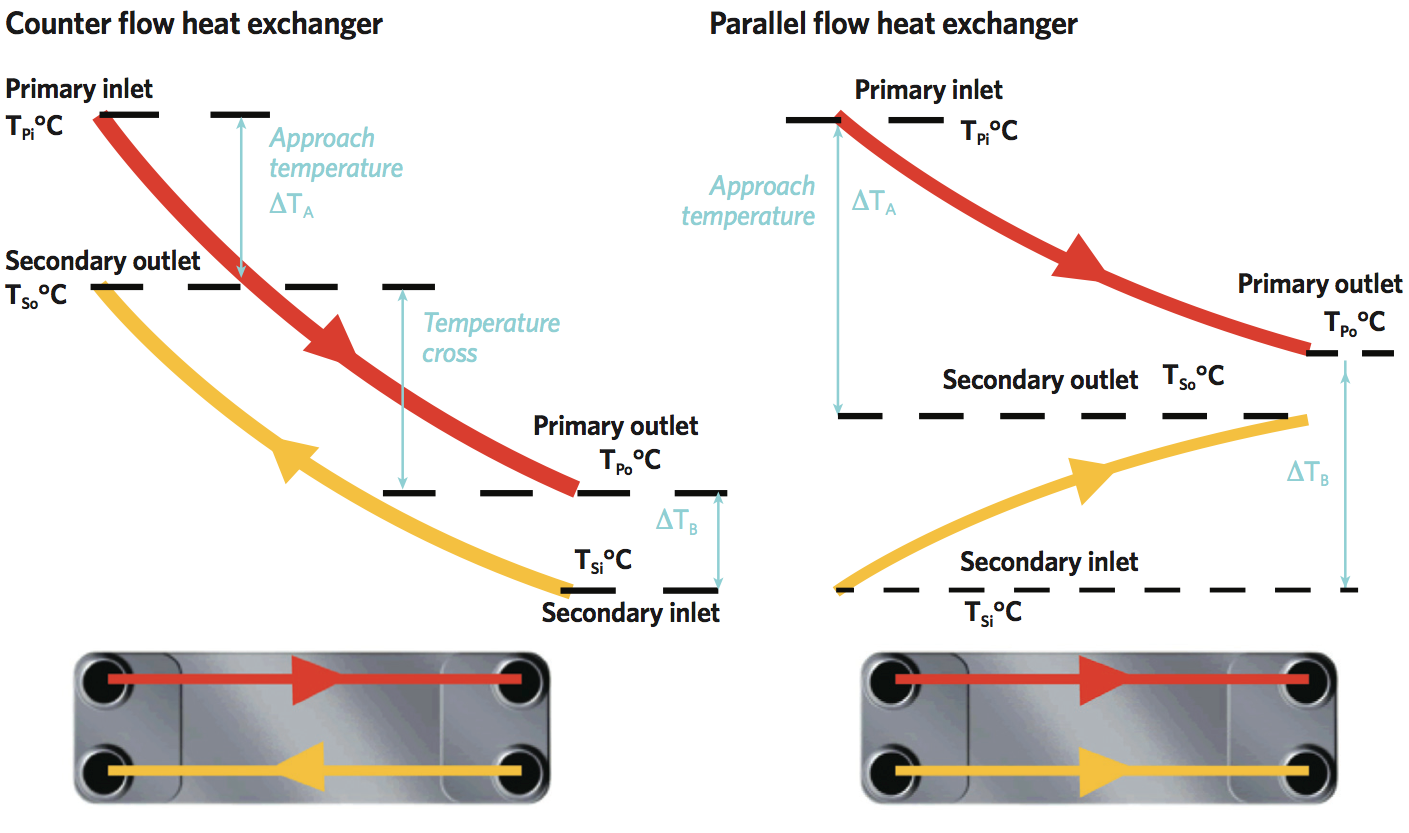

The heat exchanger design equation can be used to calculate the required heat transfer surface area for a variety of specified fluids inlet and outlet temperatures and types and configurations of heat exchangers including counterflow or parallel flow.

Counter flow heat exchanger equations.

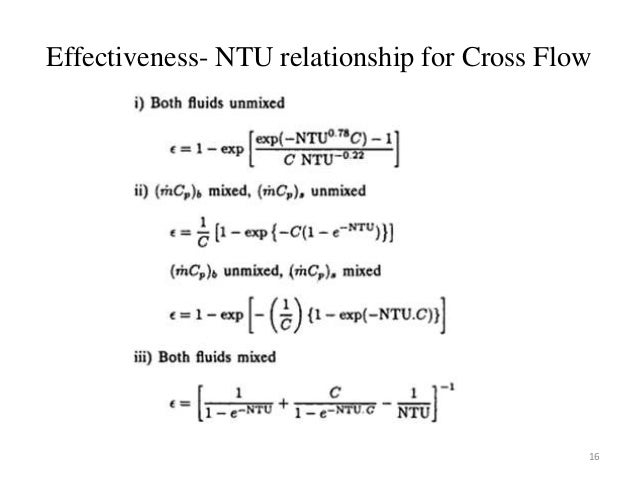

The effectiveness ntu relationships for crossflow heat exchangers and various types of shell and tube heat exchangers can be derived only numerically by solving a set of partial differential equations.

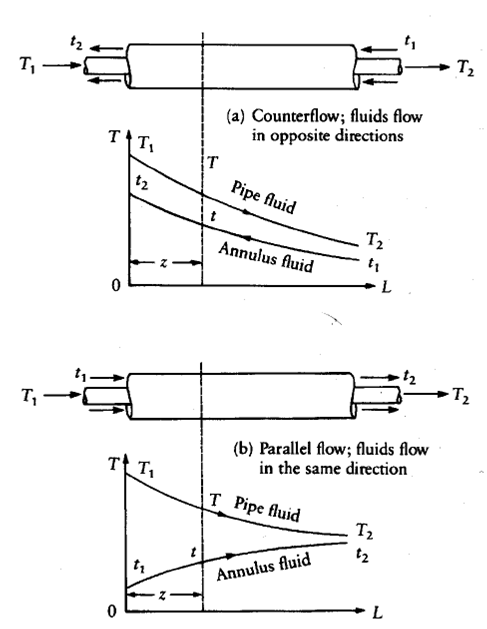

In a parallel flow exchanger both fluids in the heat exchanger flow in the same direction.

Using these shell tube heat exchanger equations.

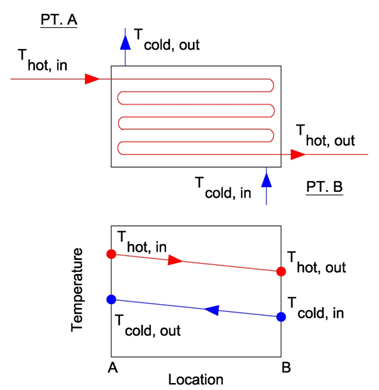

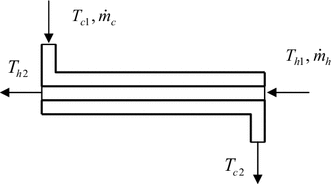

Consider a parallel flow or counterflow heat exchanger consisting of fluid 1 fluid 2 and the wall separating these two fluids.

Often engineers prefer to use a heat exchanger design software to create a heat exchanger model.

We combine these two types together with an index n to indicate the flow direction of fluid 2.

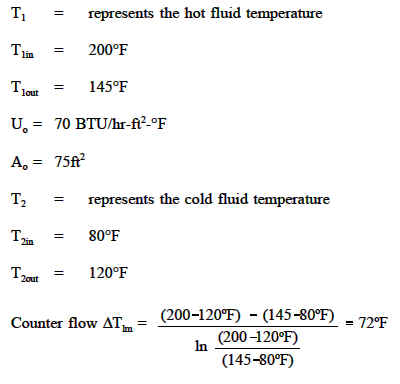

For counter current flow heat exchanger with.

For a parallel flow heat exchanger n 0 and for a counterflow heat exchanger n 1.

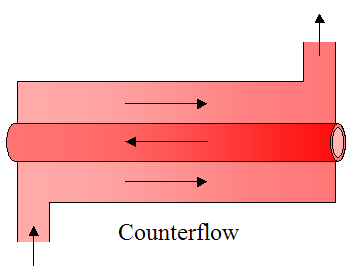

A counter flow heat exchanger is one in which the direction of the flow of one of the working fluids is opposite to the direction to the flow of the other fluid.

So there is no analytical formula for their effectiveness but just a table of numbers or a.

The simplest heat exchanger is one for which the hot and cold fluids move in the same or opposite directions in a concentric tube or double pipe construction.

We already saw that the design of a shell and tube heat exchanger is an iterative process.